P12 Phaeton

Introduction

Over the course of the last 3 years, Team PrISUm has fully built and designed one car and is currently designing another one. We have raced in 3 races, attended countless outreach events and have had over 100 new members walk in and out of our doors. Team PrISUm is now on its 12th project, Phaeton: A 3-wheeled space frame vehicle with a carbon fiber body. The mechanical team set out to create a thinner carbon fiber body and aluminum frame – decreasing our drag. The electrical team set out to build a safer, more reliable electronic design – adding ground isolation, ribbon connectors, and enhanced battery module communication. This new faster, lighter, and higher capacity car surpasses its predecessor Hyperion and is going to be team PrISUm’s most competitive design yet. Our energy storage has upgraded to new BostonPower batteries. These feature the same heat tolerances (60 degrees Celsius) as Hyperion but have a higher capacity (4KWh up from 3.5 KWh). Nearly the same solar cells from Hyperion will be used on Phaeton but will only cost two thirds of the price due to a drop in solar-cell costs over the years. Phaeton will use a new lighter Wave Sculptor motor controller ($6000 a piece) for converting DC to the 3-Phase AC signal that powers the same NGM motor PrISUm has been using for the last 15 years. This is where my personal perspective comes into this story. PrISUm, in reality, is split between core members (those who try hard to make an impact or have been around awhile) and peripheral members (often new members who join the team; learning and growing from the core members). The magic of solar car is that you get to see people jump this band gap every semester. Everyone who has been on the team has had the chance to learn a little more about engineering, organizations, and themselves. Myself, along with other directors, had the goal of facilitating this process as fast as possible. Now in the Fall semester of 2013, Phaeton will soon start taking shape.

Logan Scott

Phaeton 2 was built off the frame and shell of Phaeton, the team’s 12th solar vehicle. Due to the long term goal set of competing in the 2017 Bridgestone World Solar Challenge, PrISUm decided to rebuild Phaeton instead of constructing a new vehicle from the ground up. In order to make the car competitive for the 2016 circuit, the vehicle was completely stripped to bare carbon fiber and rebuilt with new electronics, suspension, and fairings. Due to this effort, the team was able to increase the aerodynamics of the vehicle, increase the battery capacity, and increase the motor efficiency. This came at a slight cost, as the project was finished just in time to ship to the Formula Sun Grand Prix. The minimally tested vehicle had reliability issues that caused delays during the race. These delays, coupled with bad weather, made for a race to remember for all who attended.

Media:

Vehicle Specifications

| Mechanical |

| Weight: 390lbs |

| Chassis: 6061-T6 Aluminum space frame |

| Electrical |

| Batteries: 5kWh Lithium-Ion |

| Solar Array: 391 SunPower C-60 Monocrystalline silicone, 22.3% efficiency, 1200 peak watts |

| Motor: Mitsuba M2096-III Brushless DC |

Where’s it at now?

On November 5th of 2017, PrISUm said farewell-for-now to Phaeton as she continues her journey as one of the most successful solar race cars to ever come out of our team. Similar to the donation of Hyperion’s shell and chassis to Appalachian State University, Phaeton was donated to the University of Iowa Society of Mechanical Engineers to kick-start their solar car program.

The donation of Phaeton’s structure and body acted as a significant head-start on designing and racing U of I’s first solar car in a number of years. Moving forward PrISUm will continue to mentor that team as they continue to design all electrical and mechanical systems for Phaeton’s new life. Their plan is to take Phaeton on a tour of Iowa to grow awareness of their program and also as a fundraiser with the hopes of competing her in the next Formula Sun Gran Prix.

Races

ASC / FSGP 2014

2015 Formula Sun Grand Prix: 1st place

2014 American Solar Challenge: 3rd place

2014 Formula Sun Grand Prix: 5th place

The 2014 American Solar Challenge started in Austin, Texas and ended in Minneapolis, Minnesota.

Day 1: Sat, July 21: Start in Austin, Texas; must reach Weatherford, TX checkpoint.

Day 2: Sun, July 22: Finish in Norman, Oklahoma.

Day 3: Mon, July 23: Start in Norman, OK; must reach Wichita, Kansas checkpoint.

Day 4: Tue, July 24: Finish in Overland Park, KS.

Day 5: Wed, July 25: Start in Overland Park, KS; must reach stage stop in Omaha, Nebraska.

Day 6: Thu, July 26: Start in Omaha, NE; must reach Ames, Iowa checkpoint.

Day 7: Fri, July 27: Finish in La Crosse, Wisconsin.

Day 8: Sat, July 28: Start in La Crosse, WI; finish in Minneapolis, Minnesota.

The 2014 and 2015 Formula Sun Grand Prix were held at Circuit of the Americas in Austin, Texas.

ASC / FSGP 2016

2016 American Solar Challenge: 7th place

2016 Formula Sun Grand Prix: 9th place

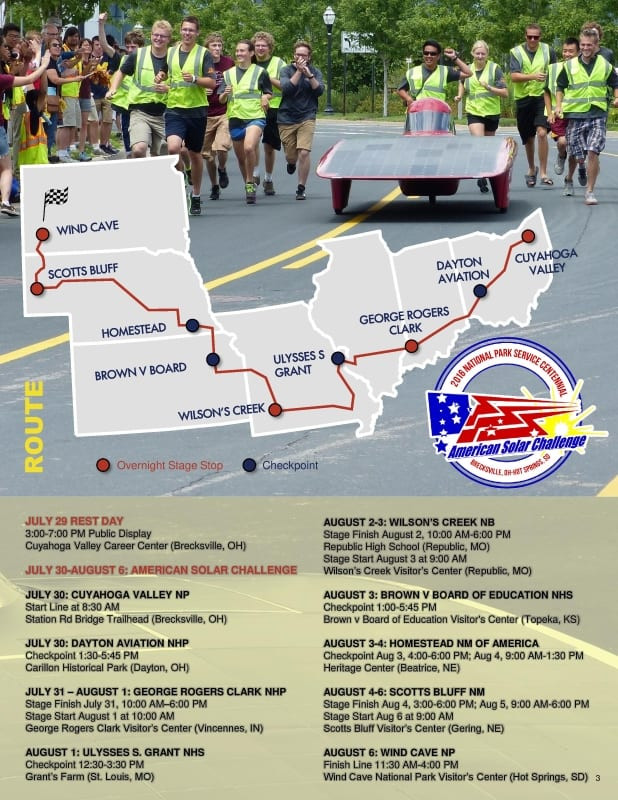

The 2016 American Solar Challenge started in Brecksville, Ohio and ended in Hot Springs, South Dakota. This race was in conjunction with the National Park Service for their centennial celebration.

Day 1: Sat, July 30: Start in Brecksville, Ohio; must reach Dayton, OH checkpoint.

Day 2: Sun, July 31: Finish in Vincennes, Indiana.

Day 3: Mon, August 1: Start in Vincennes, IN; must reach St. Louis, Missouri checkpoint.

Day 4: Tue, August 2: Finish in Republic, MO.

Day 5: Wed, August 3: Start in Republic, MO; must reach Beatrice, Nebraska checkpoint.

Day 6: Thu, August 4: Must reach Gering, NE checkpoint.

Day 7: Fri, August 5: Finish in Scottsbluff, NE.

Day 8: Sat, August 6: Start in Scottsbluff, NE; finish in Hot Springs, South Dakota.

The 2016 Formula Sun Grand Prix was held at the Pittsburgh International Race Complex in Pittsburgh, Pennsylvania. When PrISUm arrived, they noted that the top speed of the vehicle was severely lacking, topping out at 45 mph. In order to increase this speed, members began the designs of what became a Turbo-encabulator. Thanks to the help of Rockwell Collins engineers Steve Goode and Bryan McCoy, the team designed, tested, and built a boost-voltage system at the track. This system allowed the battery pack voltage to be increased from 86V to 110V. This higher voltage allowed the motor to spin at a higher speed, pushing Phaeton to speeds of 60 mph.